Measuring a client’s problem and voicing all stakeholder insights are recorded, researched and then taken to the design board to build a new design solution closer to the business need and performance.

Testing a product with varied load range enables us to visualize a heavy duty scenario, when the pallets are on a live location. We iterate faster with our visual tools and after all accuracy is what we need.

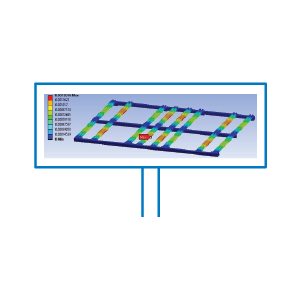

To know the nature of your pallet through our the surface and knowing the pressure points is crucial for unknown load factors. We can now control the pallet’s limits of bending & breaking, making pallets far more superior than ever.

Knowing real factors and working in real environments have shaped a lot of our knowledge in live load testing, our superior and 30 yr old experience in this has helped us develop such customized testing techniques to test pallets from 360 degrees.

A perfect design can only promise much, but testing on job makes it a confident solution. How we have developed our confidence in years is through our customer’s on job testing after a series of solution finding and iterations. It’s indeed a real test.

Our Scalable deliveries are largely a function of how faster and correctly the smallest units are built. Our scalable production methods and infrastructure are client centric and enables us with the least time to deploy once the core processes are over.