With the fast-changing business landscapes, industries are investing more towards replacing or upgrading their existing range of material handling machinery. With the advent of high-level machinery and software like AI, IoT systems, etc the industries have a pressure of being more flexible with the changing environment. To make the task easier and hassle-free various new applications of these technologies are being adopted by industries.

The India Automated Material handling market was valued at $1353.8 million in 2020 and is expected to reach up to $2739.34 million by 2026. The Global Automated Material handling industry stood at a value of $32.1 billion in 2020 and is expected to grow at a CAGR of over 7% by 2026. In the contemporary eras, one of the important aspects of industries is their logistics and supply chain management, which helps in the increase of their total profit shared with the world.

Digital Twin is a new application of these leading technologies for warehouse management, material handling, transportation, and logistics that can enhance your industrial logistics performance. With the evolution of sensors and network technologies, we are able to link offline physical realities to digital models. This helps in the reflection of changes experienced by objects in the physical world into a digital playground by connecting itself to the physical object or instrument and generating updates with changes in the object’s state, condition, or optimization. Insights generated from the model allow predictive decisions to be made about the physical object, which can be controlled with precision. In layman’s terms, a Digital Twin is a virtual model of a real “thing”, which adds value through visualization, analysis, prediction, or optimization.

A few of the applications of Digital Twin in the material handling industry are explained briefly below with respect to various stages of the supply chain like packaging, shipments, warehouse & distribution centers, and its implementation in the global logistics network as a whole:

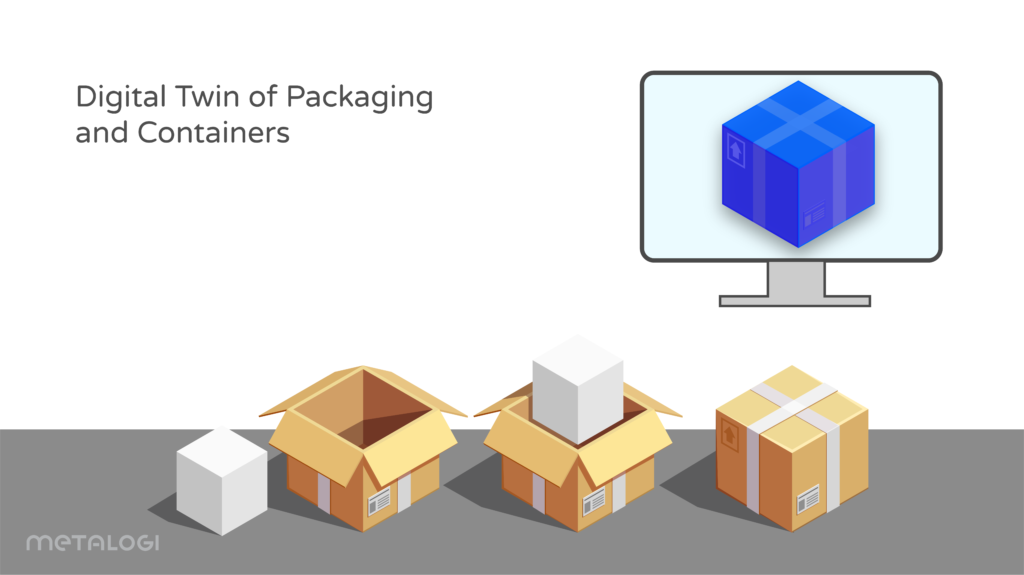

1 Digital Twin of Packaging and Containers:

In large-scale manufacturing industries products transiting through logistics networks are enclosed in protective enclosures, the design, monitoring, and management of packaging and containers pose a number of challenges for the logistics networks. For instance, e-commerce growth is contributing to a growth in demand, seasonal volatility, and packaging variety that, in turn, generates significant waste and translates to reduced operational efficiency.

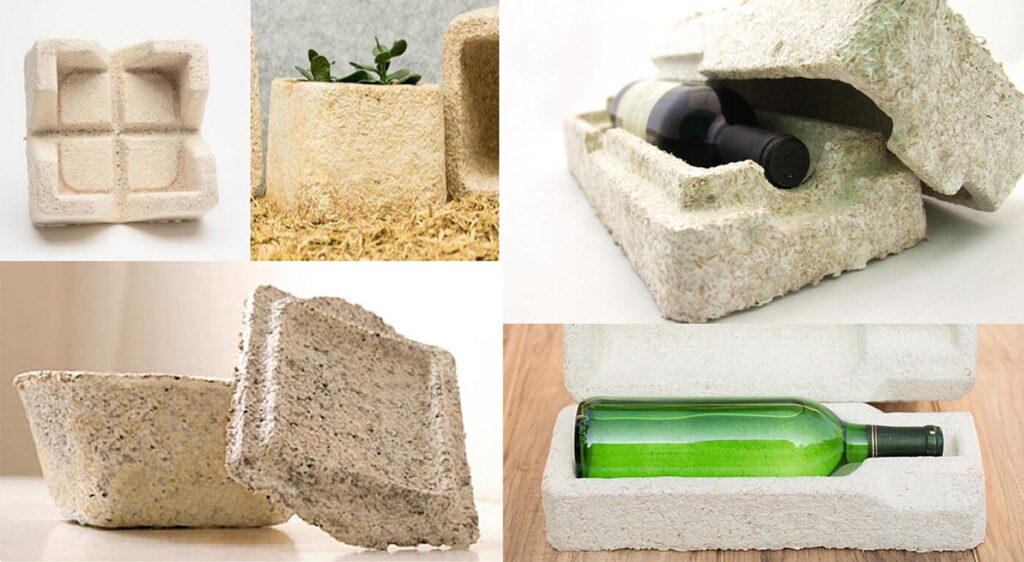

Material digital twins can be used to develop more sustainable packaging materials. To improve sustainability, companies are looking into the use of compostable plastics and other new materials. Its low cost has inspired numerous industries to implement the technology in their environment.

For example, IKEA is replacing plastic foam with alternatives grown from mushrooms to make their products more sustainable. Manufacturing industries use material digital twins to analyze the effects of using alternative materials for a product for a sustainable future.

Another leading example is the partnership between DHL and food packaging manufacturer Tetra Pak to simulate all activities and machinery using a digital twin at one of their warehouses. It allowed them to study the movement of packages and the functionality of machinery to enhance productivity.

With the help of 3D photographic technologies, developed by German startup Metrilus, industries can create a model of the reusable containers used as ocean containers, aircraft ULDs, etc. allowing the automated identification of potential problems such as internal damages, cracks, dents, etc, this along with the container’s historical data makes it easier to make predictive decisions about whether the specific asset should be repaired, or eliminated. Besides, it helps to resolve any kind of flaws in the containers or rough handling caused by the mishaps in the supply chain at any point.

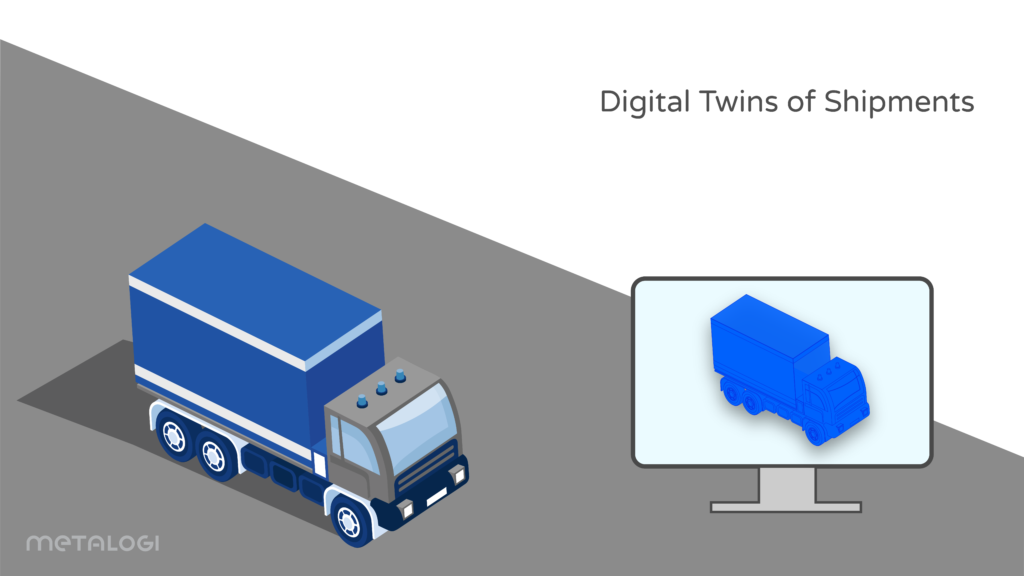

2. Digital Twins of Shipments:

While maintaining an end-to-end supply chain, containers transit through numerous shipping hubs where they are managed by various contrasting carriers, they are also affected by the temperature, packaging orientation, shock, and vibrations during the journey. Digital twinning of sensitive materials will bring next-level visibility of the item and its packaging in every transit, this helps company owners to ensure product protection and optimize utilization of packaging strategies. Digital twins can be seen as a strong model that helps to deal with high-level cyber-security threats. They are being reconstructed in a way that they not only protect the exterior cyber-security threats caused by third-party interventions but also look into the cyber-security threats that are caused internally due to internal complexities. The technology has the capacity to modernize and optimize manual-intensive enterprise that involves highly specialized systems that require continual inspection and repair. During the shipment of sensitive, high-value products, such as pharmaceuticals and delicate electronic components, sensors that monitor temperature, package orientation, shock, and vibration are incorporated. Companies like Roambee, Blulog, Kizy, and others have developed up-to-the-minute versions of these sensors that allow continuous data transmission during the progress of a shipment. A shipment digital twin would act as a storehouse for the data collected by these sensors and can use it in fresh ways.

3. Digital Twins of Warehouse and Distribution Centers:

Warehouse digital twins can support the design and layout of upcoming facilities, allowing companies to utilize more space and optimize the movement of products, personnel, and material handling equipment. They could combine a 3D model of the facility with IoT data collected in connected warehouse platforms. It is seen that warehouses today are implementing more automation techniques in their manufacturing units, a digital twin can be constantly updated with data harvested from these technologies. lt also allows optimization of the performance of these automation systems like drone-based stock counting systems, automated guided vehicles, goods-to-person picking systems, etc by using sensor data, simulation, and monitoring technologies to reduce energy consumption.

The 3D facility data can also be used to increase the productivity of warehouse personnel. Companies can deploy virtual-reality learning tools or augmented-reality picking systems which provide a valuable data stream to leverage in warehouse digital twins. As an example, Google Glass Enterprise Edition or Microsoft HoloLens are tools used by the DHL supply chain today, they have a significant impact on the design, operation, and optimization of the logistics infrastructure of the company.

4. Digital Twins of Global Logistics Networks:

Only a fraction of logistics infrastructure consists of warehouses and distribution centers, the flow of goods from source to the destination depends on various other elements including vehicles, information systems, and more importantly, people. Cargo airports and container ports are the best examples of such complex, multi-stakeholder environments.

To make the task uncomplicated the Singapore Port Authority is now working with a team of partners including the National University of Singapore, to develop a digital twin of the country’s new mega-hub for container shipping. With the guidance of University professor Lee Hoo Hay, the initiative’s technical and research development, the new approach is already in action and has started showing benefits in its designing stage. In due course, the digital twinning technique will help in choosing the optimum berthing location for a vessel of any given size, taking into account the assets, space, and personnel required for loading and unloading operations and will also be able to share resources between multiple vessels at a given time. This kind of bold and complicated task will require each and every organization within a port or airport to have an operational digital twin of their own concerning system, and the ability to share suitable data whenever there is a demand for the same.

These are a few examples of digital twin technology in the material handling industry, as well as its potential evolution, which will assist firms in a variety of industries enhance productivity and transform the way predictive maintenance and extensions are performed.

Metalogi is one of the leading Indian brands in logistic performance packaging. It provides professional packaging solutions to industries for various use cases namely exports, warehousing, and material handling. To know how to get logistic performance packaging to your organization, visit www.metalogi.in or connect with us at info@metalogi.in